Tel:0086-574-6347 1043

Fax:0086-574-6347 1658

E-mail:hgjx@cxhgjx.com

Website:www.cxhgjx.com

Website:en.cxhgjx.com

Add:No.718, Weisan Road, industrial park, Andong Town, Hangzhou Bay New Area, Ningbo

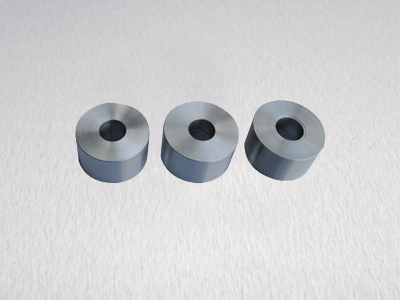

Sketch

The roller bearing is damaged and the dovetail guide rail is a line touch rolling bearing. The load capacity is large, and the key is to bear the axial load. The friction between the turnover body and the edge of the ferrule is small, which is suitable for high-speed operation. According to whether the ferrule has a flange, it can be Nu, NJ, NUP, N, NF and other single row cylindrical roller bearings, and NNU, NN and other double row cylindrical roller bearings. The rolling bearing is a separable structure with inner hole and outer side.

Cylindrical roller bearing with inner hole or outer side without flange, in which the ring and outer side can move radially, so roller bearing can be used as random end rolling bearing. One side of the inner ring and the outer side has double ribs, and the other side has a cylindrical roller bearing with separate ribs, which can bear a certain level of radial load. Generally, thick steel stamping die holder or alloy copper turning solid line holder is used. But also part of the application of acrylic resin molding cage.

Rolling bearing characteristics

1. The rotary roller bearing and dovetail guide rail are in line contact or out of repair contact, with large axial bearing capacity, suitable for bearing heavy load and impact load.

2. Small friction resistance, suitable high speed, limit speed ratio close to deep groove ball bearing.

3. The n-type and nu-type can be moved radially, which can integrate into the transformation of the relative parts between the shaft and the casing caused by thermal deformation or installation deviation, and can be used as the support plate at random end.

4. The production and processing requirements for the shaft or seat hole are high. After the installation of the rolling bearing, the relative inclination of the outer center line shall be strictly controlled to prevent the contact stress concentration.

5. The inner hole or outer side can be separated to facilitate installation and disassembly.