Tel:0086-574-6347 1043

Fax:0086-574-6347 1658

E-mail:hgjx@cxhgjx.com

Website:www.cxhgjx.com

Website:en.cxhgjx.com

Add:No.718, Weisan Road, industrial park, Andong Town, Hangzhou Bay New Area, Ningbo

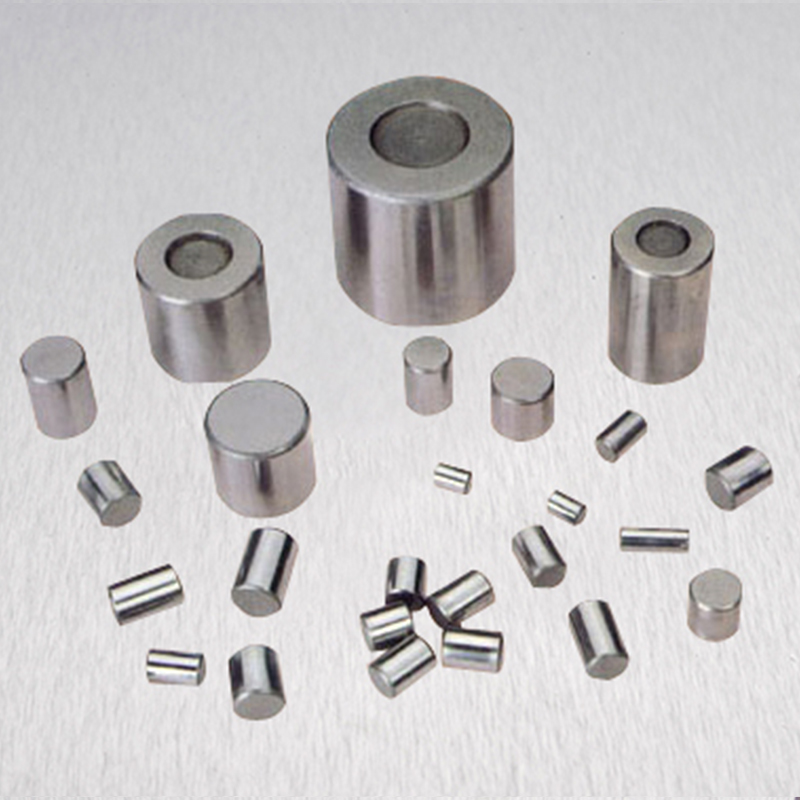

The installation of chain roller bearing is generally carried out with the specification of chain roller sleeve. At this time, the motor shaft will scrape the needle because of its own fillet. With the cylindrical roller bearing moving slowly in the motor shaft, the chain roller or auxiliary sleeve will gradually withdraw until it is placed in the working position.

The diameter of chain roller and auxiliary sleeve shall be 0.1-0.3mm smaller than that of shaft. During installation, first apply lubricating grease to the outer inner surface of the rolling bearing, stick the needle against the inner surface (leave a gap when putting a needle), then send the specifications of the roller rolling block or auxiliary sleeve replacing the inner hole of the motor shaft or the rolling bearing into the outer hole wall, and make the inner hole point to the inner hole of the mounting shaft or the inner hole of the rolling bearing installed on the shaft, and then use stamping Machine or ball head hammer to knock and press.

The cylindrical roller bearing can also be installed in that way. The diameter of the auxiliary sleeve shall be coated with a layer of grease, which shall be sleeved into the outer side of the rolling bearing to form a circular hole between the auxiliary sleeve and the outer side of the rolling bearing, and then the needle shall be installed on the circular hole. After the needle is installed, the auxiliary sleeve can be used with the working central shaft.